Chemical

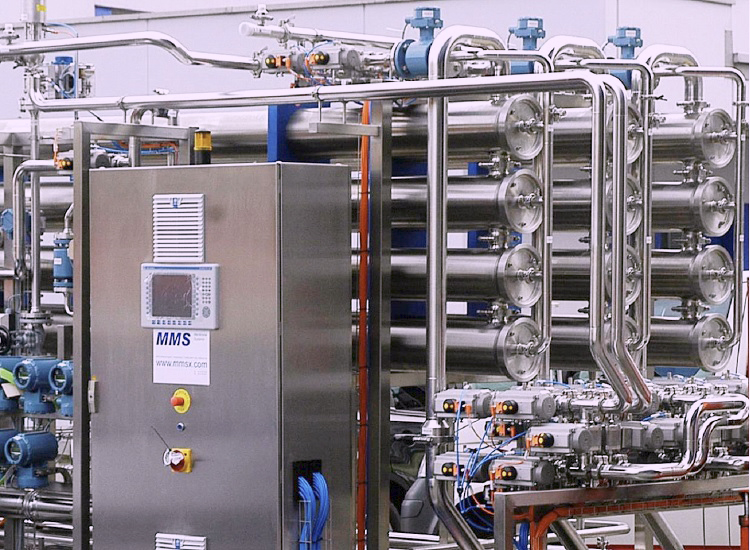

MMS membrane systems meet the highest design, safety and construction standards and are used in a wide range of applications in the chemical industry. We work closely with our customers to fully meet their expectations for function and documentation.

Demanding applications include, for example, the treatment of organic acids, which can be clarified by ultrafiltration, purified with downstream nanofiltration, and concentrated with reverse osmosis.

Versatile membrane technology is also used in: Treatment and recovery of inorganic salts, recycling of solvents, recovery and recycling of lacquers and paints, cleaning agents or macromolecules.

Download brochure MMS Membrane Filtration for Chemical Applications.

Organic Acid Clarification (UF)

- Clarification of organic acid fermentation broth with MF/UF

- Careful selection of appropriate membrane module

- Large-scale system design

Organic Acid Purification (NF)

- Purification of organic acids by retaining organic compounds

- Colour removal

- Selection of membranes with longer shelf life in acidic environment

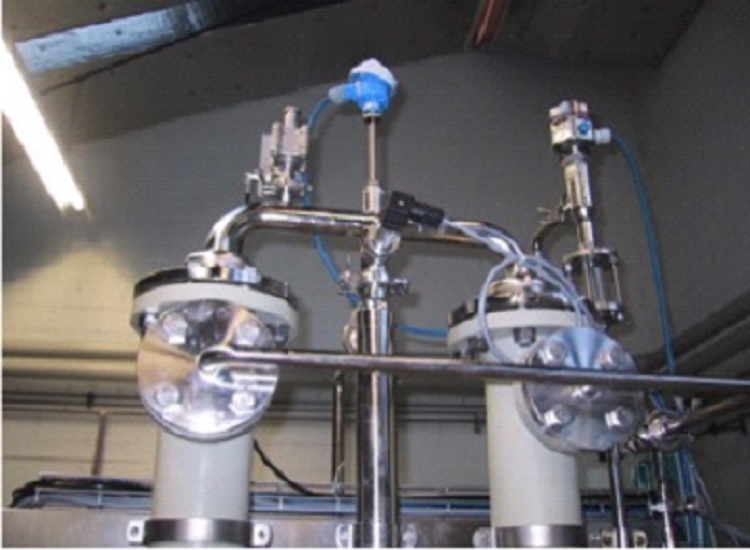

Organic Acid Concentration (RO - Cascade)

- Reverse osmosis for the concentration of organic acids

- Double RO for increased yield of acids with small molecular size

Isopropanol Purification (MF)

- Concentration of precipitants and coagulants

- Removal of larger impurities with MF

- ATEX compliant units

- Careful selection of membrane for solvent compatibility

Microfiltration of Macromolecules (MF)

- Concentration of precipitants and coagulants

- Careful selection of membrane for abrasive material

- Design of unit and selection of components to be compatible with feed material and CIP requirements

- Selection of modules to handle high viscous end-product

Inorganic Salt Concentraition (RO)

- Concentraition of inorganic salts with RO/NF combination

- Allows for evaporator cost reduction

- Multistage units are used to manage the high osmotic pressures

CIP Caustic and Acid Re-use (NF)

- Caustic and acid stable membranes

- Re-use of CIP liquids to reduce costs

- Re-use of CIP liquids to reduce wastewater

Condensate Reuse

- Condensate water reuse

- Recuperation of energy

- Pre-treatment to ensure reliable RO treatment

Water-based Paint Dewatering (RO)

- Reduction of wastewater from paint factories

- UF unit for selective recovery of colour

- RO unit for treatment of water reduce COD levels

Oil/water Separation (UF)

- Oil water separation with ultrafiltration

- Selection of correct membrane and module for reduced fouling

Clarification of Polysaccharides (MF/UF)

- Clarification from plant extracts or fermentation broth

- Specific selection of membrane module to handle high-viscous material

Go to Extracts