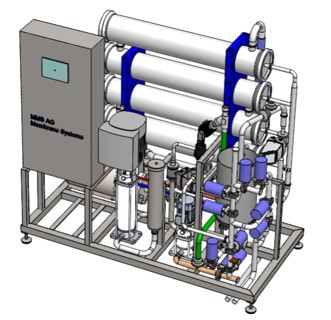

MMS Standard Machines are designed and engineered for approved applications in mainly food, beverage, and dairy applications. They were first developed for small cheese manufacturers in the Swiss Alps to concentrate whey from manufacturing small batches of Gruyere or Emmental cheese. Based on volumes in a range of 5,000 – 10,000 liters of whey for concentration by Reverse Osmosis, MMS standardized these systems to different sizes, to increase manufacturing efficiency and decrease investment cost.

Nowadays, our standard systems can be used for a variety of applications, and all systems can be individualized to customer preferences.

MMS offer several standard machines for puchase and rental:

MMS BeerMAX is a standardized Reverse Osmosis system for alcohol reduction in beer, wine and cider beverages.

Batches of 10-100 hl/day can be treated, making it an ideal unit for small and medium sized breweries.

Download brochure here and contact us for more information.

MMS MolkeMAX is a unique Reverse Osmosis (RO) System for whey concentration of 5,000 - 20,000 liters of whey per day. An ideal unit for small and medium sized cheese producers.

Download brochure here and contact us for more information.

MMS Alpine Systems are unique Reverse Osmosis (RO) systems for whey concentration of 15,000 - 150,000 liters of whey per day. An ideal filtration unit for cheese producers.

Download brochure here and contact us for more information.